What is Photo Chemical Etching?: In simple terms Photo Chemical Etching uses both chemicals and a photo lithography method to simply remove unwanted metal from defined locations leaving desired metal in defined areas to produce a part(s) or component(s). If the desired part can be drawn on paper or a computer, chances are the part can be Photo Etched.

General tolerances of Etched metal parts are +/-10% of the material thickness for dimensional tolerances and +/-.0002” or better for positional tolerances.

Most metallic metals can be etched, but Aabel Tech most often supplies parts etched of; Stainless Steel and other Iron Nickel Alloys, Beryllium Coppers and various Copper Alloys, Titanium and other Titanium Alloys, and numerous other alloys. If there’s question whether a metal can be etched or not, it’s always best to ask

What is Photo Electroforming?: Photo Electroforming simplistically is electro plating a desired metal in a defined area leaving a desired metal part. Electroforming is an additive process, whereas Etching is a subtractive process. Again with Electroforming, if the desired part can drawn on paper or on a computer, chances are the part can be produced using the Electroforming method.

General tolerances of Electroformed parts are +/-.0002” for dimensional tolerances and +/-.0001” for positional tolerances.

Many metals can be Electroformed or electro deposited, but Aabel Tech most often only supplies Electroformed parts produced of either Hard or Soft Nickel. If there are any questions, please don’t hesitate to ask.

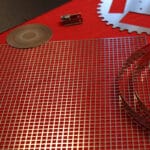

Please see Industrial Netting for any of your plastic netting, mesh or screen needs.